K25lp Throttle Control, Highlights, Understanding & More

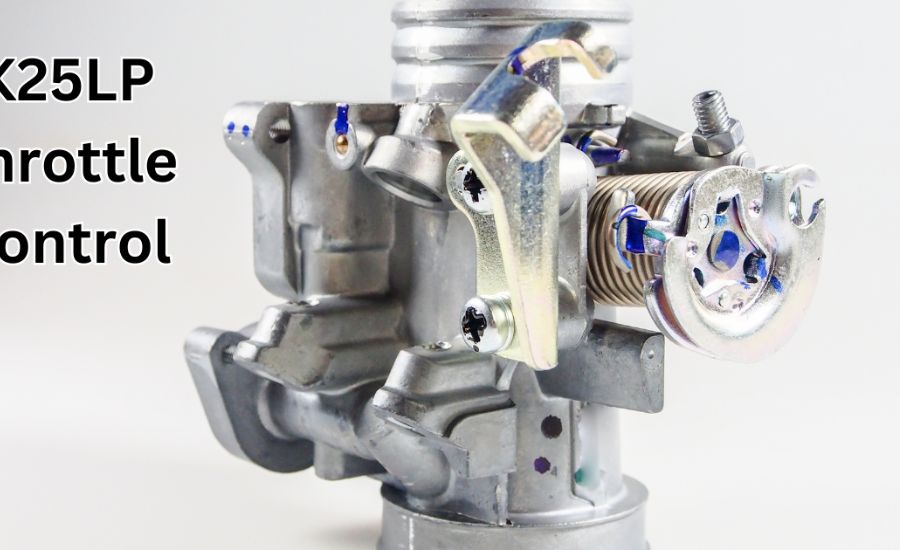

Introduction to K25lp Throttle Control

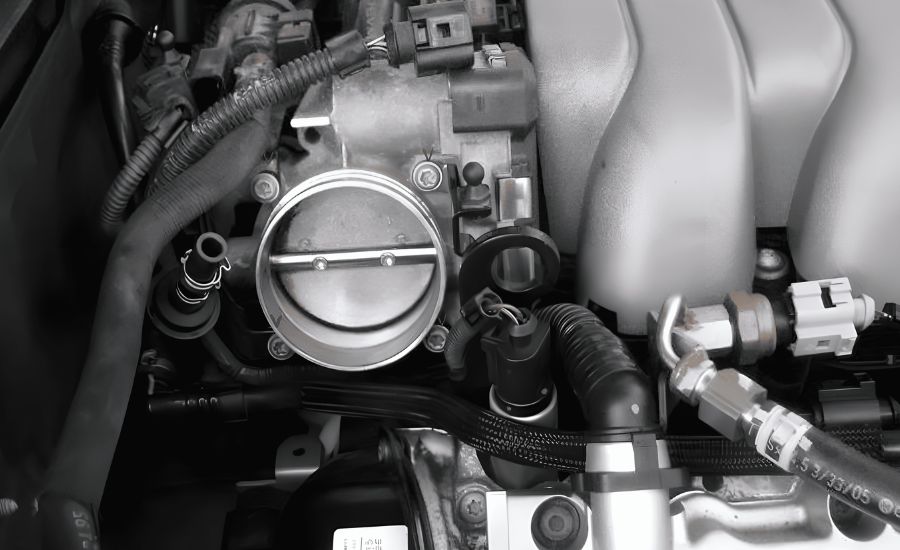

The K25LP throttle contro is a vital component in advanced motor administration, capable for directing the sum of discuss and fuel blend that enters the combustion chambers. This exact control straightforwardly impacts motor execution, control yield, and fuel proficiency. Customarily, throttle control was a mechanical framework, where a cable associated the quickening agent pedal to the throttle body.

However, with progressions in innovation, frameworks like the K25LP throttle contro have moved towards electronic throttle control (ETC). These progressed frameworks utilize sensors and actuators to oversee throttle position, advertising smoother increasing speed, improved fuel economy, and superior control, particularly beneath requesting driving conditions. The K25LP throttle contro speaks to a noteworthy jump in motor innovation, optimizing execution whereas giving more solid and responsive driving experiences.

Key Highlights of the K25LP Throttle Control

One of the standout highlights of the K25LP throttle control is its accuracy. This gadget permits for fine-tuned administration of motor speed, which is significant for errands that require correct control alterations. Whether you’re working on a sensitive operation or dealing with overwhelming loads, the K25LP guarantees that your motor runs at the ideal speed for the errand at hand.

Another key highlight is its toughness. Developed from high-quality materials, the K25LP throttle control is planned to withstand the rigors of challenging conditions. Whether it’s uncovered to clean, dampness, or extraordinary temperatures, this throttle control is built to final. Its vigorous development guarantees that it can handle customary utilize without compromising on performance.

Usercomfort is too a need in the plan of the K25LP throttle control. The ergonomic format minimizes administrator weakness amid expanded utilize, and the control instruments are deliberately set for simple get to. This consideration to detail in plan makes the K25LP not as it were useful but moreover comfortable to use.

Understanding the Significance of Throttle Control in Machinery

Throttle control plays a pivotal part in the operation of apparatus, as it straightforwardly impacts motor execution. Appropriate throttle administration guarantees that the motor runs productively, diminishing wear and tear and amplifying the life expectancy of the gear. The K25LP throttle control exceeds expectations in giving smooth and solid motor speed alterations, which is fundamental for both security and productivity.

When utilizing apparatus, exact throttle control can avoid motor strain and decrease the chance of mischances. It permits administrators to keep up a reliable speed, which is imperative for assignments that require relentless control yield, such as plowing areas, lifting overwhelming loads, or working control apparatuses. The K25LP throttle control’s capacity to offer fine alterations makes it perfect for a wide run of applications.

Installing the K25LP Throttle Control: Step-by-Step Guide

Gather the Essential Tools

Before starting the establishment prepare, guarantee that you have all the required apparatuses on hand. This incorporates Allen keys, torques, forceps, Phillips, and flathead screwdrivers. Security is too fundamental, so make beyond any doubt the motor is off and cold some time recently you begin, and wear security gloves to ensure your hands.

Remove the Ancient Throttle Control

Start by disengaging the battery if vital and guaranteeing the motor is totally off. Another, utilize the suitable apparatuses to unscrew any nuts, screws, or clips holding the ancient throttle control in put. Carefully unplug any lines or associations connected to the ancient control, guaranteeing you do not harm them amid removal.

Install the Modern K25LP Throttle Control

Align the unused K25LP throttle control with the assigned mounting focuses on your gear. Secure it solidly in put utilizing screws, jolts, or clips as required. Guarantee that all latches are fixed safely to anticipate any development or extricating amid operation.

Reconnect the Cables and Linkages

After the throttle control is secured, reconnect all cables or linkages that were withdrawn amid the evacuation handle. Double-check that they are legitimately joined and secured to anticipate any operational issues.

Test the Installation

Once everything is in put, perform a test to guarantee the throttle control is working accurately. Begin the motor and continuously alter the throttle to affirm that it reacts easily to your inputs. If everything works as anticipated, the establishment is complete.

Maintaining Your K25LP Throttle Control for Longevity

Routine Inspections

To keep your K25LP throttle control in ideal condition, customary upkeep is fundamental. Start by conducting schedule assessments to check for any signs of wear and tear. See for splits, frayed cables, free associations, or any other markers of potential issues. Tending to these issues early can anticipate encourage harm and guarantee dependable operation.

Lubrication

Lubrication is a key viewpoint of keeping up the smooth operation of the K25LP throttle control. Frequently apply the manufacturer’s suggested grease to the moving parts to decrease contact and anticipate wear. Appropriate oil makes a difference expand the life expectancy of the throttle control and guarantees that it works smoothly.

Cleaning

After each utilize, take the time to clean the throttle control. Expel any earth, flotsam and jetsam, or buildup that may have amassed amid operation. Utilize a delicate brush or cloth to wipe down the surface, and pay extraordinary consideration to zones where earth is likely to construct up. Keeping the throttle control clean makes a difference keep up its execution and avoids malfunction.

Checking for Corrosion

Metal components of the throttle control are vulnerable to erosion, particularly if uncovered to dampness. Routinely review these parts for any signs of rust or erosion. If you discover any, utilize a appropriate dissolvable to clean the influenced zone and apply a defensive coating to avoid advance damage.

Tightening Connections

Loose associations can cause whimsical throttle behavior and posture security dangers. Amid your upkeep checks, guarantee that all associations are tight and secure. If you take note any free screws or jolts, fix them to avoid operational issues.

Optimal Utilize and Care Tips for K25LP Throttle Control

Starting the Engine

To guarantee smooth motor operation, position the throttle accurately some time recently beginning the motor. Steadily increment the throttle as the motor warms up, which makes a difference accomplish a smooth begin and diminishes the chance of motor strain.

Shutting Down the Engine

When it’s time to closed down the motor, diminish the throttle to sit still steadily some time recently turning off the motor. This hone makes a difference dodge sudden shutdowns that seem possibly cause harm to the engine.

Precise Throttle Adjustments

The K25LP throttle control permits for exact alterations to motor speed, guaranteeing ideal execution for different applications. Whether you’re working overwhelming apparatus or performing fragile errands, the capacity to finely tune the throttle setting is pivotal for accomplishing the wanted results.

Using the Throttle Bolt Feature

For errands that require a consistent motor speed, utilize the throttle bolt highlight accessible on the K25LP throttle control. This include permits you to keep up a relentless speed without having to physically hold the throttle in put, diminishing administrator weakness and progressing efficiency.

Safety Considerations

Always prioritize security when utilizing apparatus prepared with the K25LP throttle control. Wear defensive adapt such as gloves and eye security to minimize the chance of harm. Moreover, continuously take after the manufacturer’s informational and proposals for secure operation to guarantee both your security and the life span of your equipment.

Safety Highlights and Considerations

The K25LP throttle control is planned with security in intellect. It incorporates a throttlelock and a returnspring to anticipate inadvertent engagement and advance secure operation. The throttle bolt highlight guarantees that once you set the wanted motor speed, it remains steady, lessening the hazard of sudden changes that seem lead to accidents.

The return spring is another vital security include, consequently returning the throttle to its unbiased position when discharged. This anticipates the motor from proceeding to run at tall speeds if the administrator loses control, advance improving the security of the machinery.

Common Issues and Investigating Tips

Even with normal upkeep, you may every so often experience issues with your K25LP throttle control. Here are a few common issues and investigating tips:

Sticking Throttle

If the throttle gets to be sticky or lethargic, it may be due to earth or flotsam and jetsam discouraging the moving parts. Assess the throttle for any buildup and clean it completely. Grease up the moving parts to reestablish smooth operation.

Loose Connections

Loose associations can cause the throttle to carry on whimsically. Check all screws, jolts, and cables to guarantee they are firmly secured. If you discover any free components, fix them to resolve the issue.

Corrosion

Corrosion on metal parts can lead to breakdown. Frequently assess for signs of rust or erosion and clean influenced regions with a appropriate dissolvable. Apply a defensive coating to avoid assist corrosion.

Throttle Not Responding

If the throttle control is not reacting as anticipated, it may be due to an issue with the linkage or cables. Check these components for any signs of harm or disengagement. Reconnect or supplant any flawed parts to reestablish functionality.

Comparing the K25LP Throttle Control with Other Models

The K25LP throttle control stands out from other models on the advertise due to its exactness, toughness, and user-friendly plan. Not at all like a few other throttle controls, which may offer constrained alteration choices or be inclined to wear and tear, the K25LP is built to give dependable execution over the long term.

When compared to comparable models, the K25LP throttle control’s ergonomic plan and security highlights make it a favored choice for experts who require exact control and reliable operation. Its strong development and ease of upkeep too make it a important speculation for those who depend on their apparatus for day by day errands.

Facts:

- Purpose: The K25LP throttle control is a critical component for managing the air-fuel mixture entering an engine’s combustion chambers, directly influencing performance, fuel efficiency, and power output.

- Technology: Transitioned from traditional mechanical systems to Electronic Throttle Control (ETC), using sensors and actuators for smoother acceleration and improved control.

- Key Features:

- Precision: Allows fine-tuned engine speed adjustments for tasks requiring accuracy.

- Durability: Built with high-quality materials to withstand harsh conditions (dust, moisture, extreme temperatures).

- Ergonomics: Designed for user comfort, reducing operator fatigue during extended use.

- Safety: Equipped with a throttle lock and return spring to ensure safe operation.

- Applications: Ideal for heavy machinery, precision tasks, and operations requiring steady engine output, such as plowing, lifting, or running power tools.

- Maintenance Tips: Regular inspections, cleaning, lubrication, and checking for corrosion ensure longevity and reliability.

- Installation: Simple step-by-step process involving the removal of old controls, proper alignment, reconnection of linkages, and testing for functionality.

- Troubleshooting: Common issues include sticking throttles, loose connections, corrosion, and unresponsive throttle controls, which can often be resolved with cleaning, lubrication, or tightening components.

Summary:

The K25LP throttle control is an advanced component for engine management, replacing traditional mechanical systems with electronic throttle control (ETC). This innovation offers smoother acceleration, improved fuel efficiency, and precise adjustments for tasks requiring fine control. Built for durability, it withstands challenging conditions, ensuring consistent performance over time.User comfort is a priority in its design, featuring ergonomic controls that reduce fatigue during prolonged use. Its safety features, such as the throttle lock and return spring, prevent accidents and ensure reliable operation.

Installation is straightforward, and regular maintenance, including inspections, lubrication, cleaning, and tightening connections, is key to its longevity. In case of issues like sticking or unresponsive throttles, troubleshooting steps are provided. The K25LP stands out for its durability, precision, and safety, making it a preferred choice for professional applications.

FAQs:

1. What is the K25LP throttle control used for?

The K25LP throttle control is used to regulate the air-fuel mixture entering an engine, optimizing performance, fuel efficiency, and power output, especially in heavy machinery and precision tasks.

2. How does the K25LP differ from traditional throttle controls?

Unlike traditional mechanical throttle systems, the K25LP uses Electronic Throttle Control (ETC) with sensors and actuators for smoother, more precise engine management.

3. What are the safety features of the K25LP throttle control?

It includes a throttle lock to maintain consistent engine speed and a return spring that automatically resets the throttle to neutral when released, enhancing safety.

4. What materials make the K25LP throttle control durable?

The K25LP is made of high-quality, robust materials designed to resist dust, moisture, extreme temperatures, and wear, ensuring long-lasting performance.

5. How do I maintain the K25LP throttle control?

- Perform routine inspections for wear or loose connections.

- Clean dirt and debris after use.

- Apply manufacturer-recommended lubricants to reduce friction.

- Check for and address corrosion on metal components.

6. What are common issues with the K25LP throttle control, and how can they be fixed?

- Sticky throttle: Clean and lubricate moving parts.

- Loose connections: Tighten screws and cables.

- Corrosion: Use a solvent to clean rust and apply a protective coating.

- Unresponsive throttle: Check linkages and cables for damage or disconnection.

7. How does the K25LP improve user comfort?

Its ergonomic design minimizes operator fatigue during long use, with controls placed for easy access.

8. Can I install the K25LP throttle control myself?

Yes, the K25LP can be installed following a straightforward process of removing the old throttle control, securing the new one, reconnecting cables, and testing functionality.

9. Why is precise throttle control important in machinery?

Precise control ensures optimal engine performance, reduces wear and tear, and enhances safety and efficiency during demanding tasks like plowing or lifting heavy loads.

10. How does the K25LP compare to other throttle control models?

The K25LP excels in durability, precision, and ergonomic design, making it a reliable and user-friendly choice for a wide range of applications.

Read More Information About Auto At blogtale.org